Leading Manufacturer Showcases Innovative Solutions for Industrial Applications

By:Admin

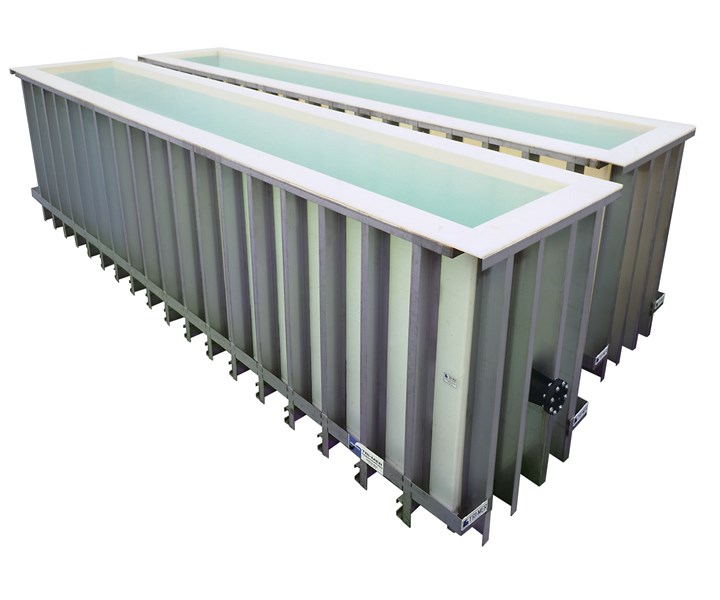

Tri-Mer Corp. is a leading manufacturer of air pollution control systems, industrial process equipment, and fluid handling systems. The company has been providing innovative solutions to a variety of industries, including furniture, automotive, and aerospace, for over 50 years. However, Tri-Mer Corp. has recently gained recognition for its innovative PU trimer system, which is designed to make the production of PU foam more efficient and environmentally friendly.

The PU trimer system developed by Tri-Mer Corp. is a unique technology that offers significant benefits to companies that produce PU foam. The system is designed to minimize waste and reduce the amount of harmful emissions released into the environment during the production process. This is achieved by utilizing a patented process that involves the simultaneous conditioning of the air and the foam. This results in a significant reduction in energy consumption and the ability to meet strict environmental regulations.

One of the most impressive features of the Tri-Mer Corp. PU trimer system is its ability to produce high-quality PU foam products consistently. This is particularly important in the furniture industry, where the quality of furniture depends on the quality of the foam used. With the PU trimer system, Tri-Mer Corp. can produce foam that meets the highest standards, ensuring that furniture manufacturers can provide their customers with products that are comfortable, durable, and long-lasting.

Another benefit of the PU trimer system is its ease of use. The system is designed to be user-friendly, providing operators with a straightforward process that requires minimal maintenance. This means that furniture manufacturers can integrate the system into their production line easily, without the need for significant capital investments.

Tri-Mer Corp. is committed to providing innovative solutions to the furniture industry and other industries that rely on PU foam. With its PU trimer system, the company is helping to reduce waste, decrease energy consumption, and meet strict environmental regulations. Moreover, the system allows for the production of high-quality foam products that are comfortable and durable. By continuing to invest in research and development, Tri-Mer Corp. is poised to remain a leader in air pollution control systems, industrial process equipment, and fluid handling systems for many years to come.

In conclusion, the Tri-Mer Corp. PU trimer system is a game-changer for the furniture industry and other industries that rely on PU foam. The system offers numerous benefits, including reduced waste, decreased energy consumption, and the ability to meet strict environmental regulations. Moreover, the system produces high-quality foam products that are comfortable and durable. By investing in the PU trimer system, companies can significantly improve their production process, reduce costs, and enhance their environmental profile.

Company News & Blog

Global Resin Capsules Market to Witness Growth Due to Increasing Demand in Mining, Construction, and Manufacturing Industries

Capsules, Organix Peroxides, Oil-based Resin Capsules, Water-based Resin Capsules, Mining, Construction, Manufacturing, Global Market Forecast.Resin capsules are widely used for anchoring, rock structure reinforcement, and reinforcing concrete. They are a critical component in construction, mining, and manufacturing industries. Resin capsules are typically used as a strong adhesive to join two materials together or to fill gaps quickly, efficiently, and evenly.The global resin capsules market is expected to experience substantial growth by 2022, bolstered by increasing demand for polyester and acrylic resin capsules across the world. According to a recent market research report, the resin capsules market is expected to grow from $972.8 million in 2017 to $1,256.2 million by 2022, at a CAGR of 5.25% during the forecast period.Polyester and acrylic resin capsules are expected to be the most popular types of resins used in the global market, due to their strength, durability, and versatility. Polyester resins are widely used in construction, transportation, and marine industries, while acrylic resins are commonly used in the manufacturing industry for a variety of applications.Organic peroxides are expected to be the most popular type of catalyst used in resin capsules, as it accelerates the curing process and reduces processing time. However, oil-based and water-based resin capsules are also gaining momentum as they are environmentally friendly, non-toxic, and easy to use.In terms of end-use industries, mining, construction, and manufacturing are expected to be the largest users of resin capsules. Resin capsules are used in the mining sector for ground support and reinforcement, while in the construction industry, they are primarily used for structural anchoring. In the manufacturing sector, resin capsules are commonly used for component assembly and bonding.Geographically, the Asia-Pacific region is expected to be the largest market for resin capsules, with China and India being the primary contributors to growth. The region's booming construction and manufacturing industries, coupled with increasing industrialization, are driving demand for resin capsules. Moreover, with growing environmental concerns, manufacturers are shifting to eco-friendly and sustainable resin capsules, thus further driving the growth of the market.In conclusion, the global resin capsules market is expected to grow substantially in the coming years, driven by increased demand for polyester and acrylic resin capsules across various industries. Manufacturers are investing in R&D activities to develop innovative products to meet the ever-changing demands of customers. As resin capsules continue to gain popularity due to their strength, durability, and versatility, the market is expected to witness significant growth throughout the forecast period.

Moisture Tolerant Epoxy Primer for Damp Concrete Surfaces: A Two-component Solution.

Quadro Coatings Inc. has recently launched a new product called CIM Moisture Tolerant Epoxy Primer EMT Resin Plus Hardener- KIT, which is specifically designed for use on green and damp porous surfaces such as concrete. This two-component solvent-free epoxy primer has been formulated to be moisture tolerant, which means that it can be used to improve the adhesion of coatings to surfaces where a dry condition cannot be achieved.CIM Epoxy Primer Resin and Hardener Kit is an excellent solution for professionals in the construction and building industry who work with porous surfaces, particularly those areas that are prone to moisture. The CIM EMT primer is designed to improve the adhesion of coatings to surfaces that are damp or greasy. This makes it an ideal product for use in areas with high humidity or where water penetrates the surface. The unique formulation of the CIM Epoxy Primer Resin and Hardener Kit ensures that it bonds strongly to the surface and provides a long-lasting finish.The CIM Moisture Tolerant Epoxy Primer EMT Resin Plus Hardener- KIT is made up of two components. The resin is the primary component, and the hardener is the secondary component. When these two components are mixed, they chemically react to form a hardened material that creates an excellent bond with the surface. This bond ensures that the coating adheres strongly to the surface and lasts for a long time.One of the significant benefits of the CIM Epoxy Primer Resin and Hardener Kit is that it is solvent-free. This makes the product environmentally friendly and ensures that it does not release any harmful VOCs (volatile organic compounds) into the air. The CIM EMT primer is also exceptionally durable and provides excellent protection against harsh environmental conditions. It has excellent chemical resistance, which means that it can withstand exposure to chemicals and other corrosive substances.The CIM Epoxy Primer Resin and Hardener Kit is easy to apply and cures quickly. This makes it an excellent product for professionals who are looking for a fast and efficient method of preparing surfaces for coating. The product can be applied using a brush, roller, or by spray application. It is also effortless to clean up with water, making it a convenient and hassle-free product to work with.In conclusion, the CIM Moisture Tolerant Epoxy Primer EMT Resin Plus Hardener- KIT is a highly efficient and versatile product that is ideal for use on green and damp porous surfaces such as concrete. The product's unique formulation ensures that it bonds quickly and strongly to the surface, providing long-lasting protection against adverse environmental conditions. The product is also solvent-free, making it environmentally friendly and easy to use. Quadro Coatings Inc. has once again proved its commitment to providing excellence in products that meet the needs of professionals in the construction and building industry.

Water-Based Resin Market Expected to Reach $10.5 Billion by 2020 with Increasing Demand in Various Industries

Water based resins are becoming increasingly popular in the market due to their eco-friendly nature, compatibility with various substrates, and superior performance properties. The global water based resin market is expected to reach $10.5 billion by 2020, and one type of water based resin that is gaining traction is water based acrylic resin powder.Water based acrylic resin powder is a type of polymer that is made by emulsion polymerization of acrylic monomers. It is a versatile material that can be used in a wide range of applications such as adhesives, coatings, inks, and others. It is also compatible with various substrates such as plastics, metals, and wood, making it an ideal choice for different end-user industries.One of the major advantages of water based acrylic resin powder is its ability to provide excellent adhesion properties. It can be used as an adhesive to bond different materials together, providing a strong and durable bond. Its adhesion properties make it ideal for applications such as laminating films on paper and bonding textiles.Another advantage of water based acrylic resin powder is its excellent film-forming properties. It can be used to form coatings on various substrates, providing a protective layer and enhancing the appearance of the substrates. Its film-forming properties make it ideal for applications such as coatings for metal and plastic substrates.In the ink industry, water based acrylic resin powder is used as a binder for pigments. Its excellent binding properties provide a strong and durable bond between the pigments and the substrate, resulting in high-quality prints. It is also easy to emulsify, making it ideal for use in water-based inks.With its eco-friendly nature and superior performance properties, water based acrylic resin powder is becoming increasingly popular in different end-user industries such as automotive, packaging, construction, and textiles. It can replace traditional solvent-based resins, which are harmful to the environment and human health.In conclusion, the water based resin market is growing, and water based acrylic resin powder is a type of water based resin that is gaining traction due to its excellent adhesion and film-forming properties. Its versatility makes it an ideal choice for different end-user industries such as automotive, packaging, construction, and textiles. Its eco-friendly nature and superior performance properties make it a great alternative to traditional solvent-based resins.

Extend the Lifespan of Your Water Tank with High-Quality Epoxy Coating in Central California

Water storage tanks are essential for homes, businesses, and industries to ensure a constant supply of clean and safe water. However, these tanks are also susceptible to corrosion, rust, and other damages due to exposure to water, chemicals, and other elements. To prevent such damages and ensure a longer lifespan for the tanks, epoxy coating for water tanks is an effective solution.What is Epoxy Coating For Water Tanks?Epoxy coating is a type of protective coating that is applied to metal surfaces to make them resistant to corrosion, rust, and other damages. This coating is made of a two-part mixture, which includes resin and hardener. When these two components are mixed, they react chemically to form a hard, durable coating that adheres tightly to the metal surface.Epoxy coating for water tanks is specifically designed to protect the metal from the harmful effects of water, chemicals, and other environmental factors. It acts as a barrier, preventing the metal from coming in contact with water and other substances that may cause damage or corrosion.Why use Epoxy Coating For Water Tanks?Water storage tanks are usually made of metals that are prone to rust and corrosion. Without proper protection, these tanks can deteriorate over time, which can lead to leaks, contamination, and other problems. Epoxy coating for water tanks provides a range of benefits that can help to prevent such issues:1. Long-lasting protection: Epoxy coating provides a durable and long-lasting protective layer that can withstand exposure to water and other elements. It can protect the metal from corrosion, rust, and other damages for several years.2. Cost-effective: Epoxy coating for water tanks is a cost-effective solution that can extend the lifespan of the tank. Instead of replacing the tank, which can be expensive, epoxy coating can be applied to restore the tank's functionality and prevent further damages.3. Reduced maintenance: Water tanks that are coated with epoxy require less maintenance than uncoated tanks. The coating prevents rust and other damages, which means fewer repairs and replacements are needed.4. Safe and clean water: Epoxy coating for water tanks is safe and non-toxic, which means it does not contaminate the water. It provides a clean and safe storage environment for the water.How is Epoxy Coating Applied to Water Tanks?The process of applying epoxy coating to water tanks is relatively simple. The tank surface is first cleaned and prepared for coating. This involves removing any dirt, rust, or other contaminants that may interfere with the bonding of the coating.Once the surface is clean, the epoxy coating is mixed according to the manufacturer's instructions. The coating is then applied to the tank surface using a spray gun, brush, or roller. The coating is left to cure for a specific amount of time, usually 24 to 48 hours, depending on the product used.After the coating has cured, it forms a hard, durable layer that provides long-lasting protection to the tank surface. The tank can then be filled with water and put into use.ConclusionEpoxy coating for water tanks is an effective solution for protecting metal surfaces from corrosion, rust, and other damages. It provides a durable and long-lasting protective layer that can extend the lifespan of the tanks and reduce maintenance requirements. When applied correctly, it provides a safe and clean storage environment for water. If you need water tank epoxy coating in Central California, Wright Tank has the expertise and experience to install high-quality coating to your metal water tank.

Premium-Quality Acrylic Eggshell Interior Paint with Excellent Hide and Seamless Touch-Ups

article on the benefits of using premium-quality, waterborne interior paints.As homeowners, it is always a priority to keep our living spaces in good condition. From redecorating to renovation, we constantly seek ways to add value and comfort to our homes. One essential aspect of keeping our interiors fresh and appealing is using high-quality paints for our walls. But with so many options available, how do we choose the best one?Fortunately, there are premium-quality waterborne interior paints that offer excellent performance, durability and environmental safety. This type of paint is made primarily of water as a solvent, and contains less to zero volatile organic compounds (VOCs) compared to their oil-based counterparts. In this article, we will explore the benefits of using premium-quality, waterborne interior paints and why they are worth investing in your home improvement project.Environmental-Friendly and HealthierWaterborne interior paints are becoming increasingly popular among homeowners because of their environment-friendly and health-conscious attributes. Unlike oil-based paints, these types of paints do not emit high levels of VOCs, which can pose a health threat to people and pets living in the house. VOCs are harmful chemicals that can irritate the eyes and respiratory system, cause headaches, dizziness and other health problems.Reducing the exposure to VOCs is especially important for households with children, pets, and the elderly. By using waterborne paints, homeowners can have peace of mind knowing that their wall coatings are safe and healthy for everyone. Furthermore, waterborne paints do not release harmful fumes during application, which makes the painting process easier and more pleasant.Excellent DurabilityAnother great advantage of using premium-quality waterborne paints is their outstanding durability. These paints are made to last longer than conventional paints, which can easily chip, fade, and peel over time. Because of their high-solid content, waterborne paints provide better coverage and adhesion, which ensures that the paint will adhere well to the surface and resist wear and tear.Additionally, waterborne interior paints are more resistant to moisture, stains, and mildew. Such resistance is especially beneficial in high-moisture areas such as kitchens, bathrooms, and laundry rooms. Waterborne paints can withstand frequent washings, which make them an excellent choice for households with children and pets.Versatile and Easy to ApplyWaterborne interior paints are also versatile and easy to apply on various surfaces. These paints can be used on a wide range of interior surfaces, such as drywall, plaster, wood, and masonry. They come in different finishes such as flat, eggshell, satin, semi-gloss and high-gloss, which allows homeowners to choose the finish that best suits their taste and décor.Waterborne paints are also easy to apply, dry quickly, and produce less odor than oil-based paints. This makes them the ideal option for DIY projects, or for homeowners who want to save time and money by hiring professional painters.In conclusion, the benefits of using premium-quality waterborne interior paints are numerous and significant. They offer health and environmental safety, superior durability, versatility, and ease of use. Whether you are transforming a single room or renovating your entire house, using waterborne paints can elevate your home improvement project to the next level. Look for well-known brands and read product reviews to ensure you get the best quality paint. With the right choice and application, you can enjoy a beautiful, long-lasting interior paint that meets your style, comfort, and personality.

Fast-Drying and Water-Resistant: All About Acrylic Paints

Acrylic Paint - A Popular Choice for Art LoversArtists of all levels and backgrounds have long been drawn to acrylic paint. It is a versatile medium, offering a wide range of colors and textures. What sets acrylic paint apart is its fast-drying nature, making it an ideal choice for projects that require quick results or multi-layered applications.Acrylic paint is formulated using a pigment suspended in an acrylic polymer emulsion. The pigment is the ingredient responsible for color, while the emulsion acts as the binding agent. When the mixture is applied to a surface, the water in the emulsion evaporates, leaving behind a flexible, water-resistant film.The History of Acrylic PaintAcrylic paint has been around for less than a century, yet it has quickly become one of the most popular mediums in the art world. Early experiments with acrylic paints began in the 1920s, but it wasn't until the 1950s that they became commercially available. At that time, artists were drawn to the medium because it offered new possibilities for experimentation.One of the pioneers of acrylic paint was the Mexican muralist David Alfaro Siqueiros, who experimented with the medium in the 1930s. In the 1950s, artists such as Jackson Pollock, Mark Rothko, and Barnett Newman used acrylic paint to create abstract masterpieces.Acrylic Paint TodayToday, acrylic paint is used by artists of all levels, from beginners to professionals. The medium is available in a wide range of colors, from bright and bold to muted and subtle. It is also available in a range of viscosity, allowing artists to create thick impasto textures or thin washes of color.One of the advantages of acrylic paint is its versatility. It can be used on a variety of surfaces, including canvas, paper, wood, and even plastic. It is also ideal for mixed media projects, as it can be used in combination with other materials such as oil pastels, charcoal, and collage elements.Another advantage of acrylic paint is its fast-drying nature. Unlike oil paints, which can take days or even weeks to dry, acrylic paints dry in a matter of minutes. This makes it an ideal choice for artists who want to layer colors quickly and experiment with different techniques.Acrylic Paint TechniquesOne of the most popular techniques used with acrylic paint is the wet-on-wet method. This involves applying wet paint to a wet surface, which allows the colors to blend and mix. Another popular technique is the dry brush technique, which involves applying paint with a dry brush to create textured, rough, and layered effects.Acrylic paint can also be used in combination with other techniques, such as glazing, impasto, and sgraffito. Glazing involves applying a transparent layer of paint over a base layer to create depth and complexity. Impasto involves applying thick layers of paint with a palette knife or brush to create texture. Sgraffito involves scratching away layers of paint to reveal layers underneath.The Future of Acrylic PaintThe popularity of acrylic paint shows no sign of slowing down. As more artists discover the possibilities of this versatile medium, the demand for new and innovative products is likely to increase. Companies such as (need remove brand name) are at the forefront of this trend, developing new formulas and colors to meet the needs of artists of all levels.Whether you are a beginner or a seasoned artist, acrylic paint offers endless possibilities for creativity and self-expression. With its fast-drying nature, versatility, and range of colors and textures, acrylic paint is sure to remain a favorite medium for years to come.

Industrial Epoxy Floor Designs: Inspiration for Your Space

Paint, Epoxy Floor Coatings, Industrial Epoxy Wall Paint, Epoxy Garage Floor Coatings, and Grey Epoxy Flooring.Are you tired of the same old boring flooring at your workplace or garage? It's time to upgrade to epoxy paint floors! Epoxy is a tough and durable coating that provides a glossy and professional finish. Northern Towers (brand name needs to be removed) offers a wide range of epoxy paint flooring solutions that are perfect for various industrial applications.Glaze Coat Epoxy Paint is a premium quality industrial-grade epoxy that can be applied to nearly any surface. It delivers a high-gloss finish that is easy to clean and maintain. This type of epoxy paint is perfect for high traffic areas such as commercial or industrial buildings, showrooms, retail spaces, garages, and even basements. Additionally, it is resistant to stains, chemicals, abrasions, and water, making it a versatile and long-lasting solution.Epoxy Floor Coatings have become a popular choice for garage and workshop flooring. This coating provides a seamless and durable flooring option. Whether you need to park your vehicles or work on a car project, this epoxy flooring solution can withstand heavy foot traffic, oil, and chemical spills. It delivers a clean and professional looking surface that will last for years.Industrial Epoxy Wall Paint is a specially formulated paint that provides excellent adhesion to most surfaces. The primary use of this epoxy paint is for concrete, cinder block, and masonry walls. It is ideal for industrial, commercial, and manufacturing facilities where walls are exposed to harsh environments and need frequent cleaning. Industrial Epoxy Wall Paint is durable and provides a high-gloss finish that is easy to maintain.Epoxy Garage Floor Coatings are a perfect solution to enhance the look of your garage and extend the life of your concrete floor. This DIY solution is an easy and affordable way to achieve a showroom-like appearance for any garage. It is easy to clean and creates a slip-resistant surface, making it a safe option for a workspace or walking area.Grey Epoxy Flooring is an ideal choice for commercial and industrial locations that require a durable and long-lasting flooring solution. Additionally, grey epoxy flooring offers a neutral and versatile color that can be used in almost any environment. This type of flooring delivers a high-gloss finish that is easy to maintain and perfect for high-traffic areas.In conclusion, epoxy paint flooring solutions are an excellent choice for commercial, industrial, or even residential applications. The different types of epoxy paint floors available offer varying benefits like resistance to stains, durability and easy maintenance. Additionally, they can enhance the look of any space and provide a long-lasting solution. Northern Towers (brand name needs to be removed) offers a wide range of epoxy paint floors solution, including Glaze Coat Epoxy Paint, Epoxy Floor Coatings, Industrial Epoxy Wall Paint, Epoxy Garage Floor Coatings, and Grey Epoxy Flooring. Upgrade your floors with these excellent solutions today!

Unlocking the Potential of Epoxy Resin for Wood: A Comprehensive Guide on Usage and Color Options

and Part B, wood epoxy resin, epoxy resin for wood, clear epoxy resin for wood.Epoxy resin has become a go-to solution for woodworking projects. Not only does it give a beautiful, glossy finish to woodworking projects, but it also provides an excellent protective layer to the wood material. Epoxy resin for wood can be used in numerous ways and available in different colors, including clear. It has many advantages over traditional wood finishes, making it a popular choice in the woodworking community.In this blog post, we will discuss everything you need to know about wood epoxy resin and how to use it.What Is Epoxy Resin?Epoxy resin is a two-part chemical compound used for bonding, sealing, and coating. It is made up of two components, Part A and Part B. Part A consists of the resin, while Part B consists of the hardener. When the two components are mixed, a chemical reaction takes place, resulting in the epoxy curing and hardening.Acrylic Epoxy Resin Part A and Part BAcrylic epoxy resin, like traditional epoxy resin, is a two-part chemical compound. However, it has additional benefits over traditional epoxy resin. Acrylic epoxy resin is a more flexible and durable material, making it ideal for surfaces that may require more flexibility, such as countertops or floors. It is also UV resistant, which is beneficial for outdoor projects that will be exposed to sunlight.Wood Epoxy ResinOne of the most popular uses for epoxy resin is in woodworking projects. Wood epoxy resin provides a beautiful, glossy finish to woodworking projects, while also providing a protective layer to the wood material. It can be used to fill cracks, holes, and gaps in wood, creating a smoother surface. It can also be used to prevent rot and decay in wood material.Clear Epoxy Resin for WoodClear epoxy resin is ideal for woodworking projects as it allows the natural grain of the wood to shine through. It provides a crystal clear, glossy finish that enhances the beauty of the wood material. Clear epoxy resin is also UV resistant, which means it won't yellow over time when exposed to sunlight.How to Use Epoxy Resin for WoodUsing epoxy resin for wood is relatively straightforward. Here is a step-by-step guide on how to use epoxy resin for woodworking projects.Step 1: Prepare the wood surfaceStart by preparing the wood surface. The wood surface should be clean, dry, and free of any debris. Sand the wood surface with fine-grit sandpaper to create a smoother surface. If filling gaps or holes, ensure they are clean and dry before applying the epoxy.Step 2: Mix the epoxy resinMix the Part A and Part B components of the epoxy resin according to the manufacturer's instructions. Mix thoroughly to ensure the two components are fully blended.Step 3: Apply the epoxy resinApply the epoxy resin to the wood surface using a brush or roller. Work in thin layers, allowing each layer to dry and cure before applying the next. Use a heat gun or torch to remove any bubbles that may form when applying the epoxy resin.Step 4: Sand the surfaceOnce the epoxy resin has fully cured, sand the surface with fine-grit sandpaper to create a smooth finish. Apply a second layer of epoxy if necessary.ConclusionEpoxy resin for wood is an excellent solution for woodworking projects. Whether you're filling gaps, holes, or providing a glossy finish, epoxy resin provides a protective layer while enhancing the natural beauty of the wood. Clear epoxy resin is ideal for showcasing the natural grain of the wood material while also providing UV resistance. Whether you're a beginner or a seasoned woodworker, epoxy resin is a versatile material that should be a part of any woodworking toolkit.

High Solid Clear Coat Kit for Automotive Applications

U-POL 2082 HS Clear Coat 2:1 %LT + Hardener 2030/25 2.5LT Kit Has Taken the Automotive Industry by StormClear coating is one of the final stages to a fantastic looking paint job and no one knows this better than U-POL. The British company has gone above and beyond to create a line of premium automotive coatings that are quickly gaining notoriety throughout the industry. The U-POL 2082 HS Clear Coat 2:1 %LT + Hardener 2030/25 2.5LT Kit is the latest addition to the company’s arsenal of high-performance products.The company’s line of coatings is famous for their unbeatable quality and the 2082 HS Clear Coat is no exception. It’s a scratch and chemical resistant coating that provides a spectacular mirror-like finish. It has been designed with a 2:1 mixing ratio, has an impressive gloss factor of 90°, and is highly resistant to weathering, yellowing, and fading.The product itself is a two component, high-solid, VOC compliant clear coat that stands out in all aspects. It’s mostly used to provide a showroom finish on top of base reflector and solid colours. But the clear coat’s potential doesn’t stop there, it’s also great for the enhancement of bodywork. It can be added to plastic repairs and is even suitable for use on painted surfaces that need restoration.The U-POL 2082 HS Clear Coat 2:1 %LT + Hardener 2030/25 2.5LT Kit comes complete with a top-quality hardener that makes it even more durable. The hardener provides a chemical reaction that increases the number of crosslinks within the coating, giving it a longer life span. Mixing the clear coat and the hardener at the right ratio ensures you get the most out of your new product.The kit’s packaging deserves mention, with its 2.5L tin packaging and practical screw-on lid. The lid makes it possible to save some of the unused product after application for later use. The innovative design helps extend the life of the remaining product, which can be used on a different vehicle or for small touch-ups.The U-POL 2082 HS Clear Coat 2:1 %LT + Hardener 2030/25 2.5LT Kit has taken the automotive industry by storm. Users have reported success in its application on various vehicles and even reported it could be easier to use than other clear coats in the market. The clear coat has altered the way professionals and hobbyists alike apply paint to their creations.U-POL is renowned for its research, quality, and innovation, making them a preferred choice globally. The company has been producing excellent automotive coatings for the past seventy years. Over the years, U-POL has become one of the market leaders in automotive refinish.The 2082 HS Clear Coat is just one of U-POL's stellar products. The company has a wide variety of coatings that aim to provide perfection and extraordinary finishes. U-POL products are not just about high-quality results. The brand's products are also environmentally friendly, and the enterprise is committed to manufacturing products that reduce the carbon footprint of the automotive industry. ConclusionIn conclusion, U-POL 2082 HS Clear Coat 2:1 %LT + Hardener 2030/25 2.5LT Kit is a revolutionary product that has taken the automotive industry by storm. It’s scratch and chemical resistant, easy to use, and provides a spectacular mirror-like finish. The product is complete with a top-quality hardener, adding durability. The clear coat is environmentally-friendly and is aimed at reducing the carbon footprint of the automotive industry. With its practical packaging, the U-POL 2082 HS Clear Coat 2:1 %LT + Hardener 2030/25 2.5LT Kit is the perfect addition to any garage, whether you work in the automotive industry or are just an enthusiastic hobbyist.

Chemical-Resistant and Anti-Slip Coating Suppliers with Resin Repair Services

RepairsIf you are looking for chemical resistant systems and anti-slip coatings, then you have come to the right place. We are a leading supplier of high-quality industrial chemicals and coatings that are specially designed to provide maximum protection against chemical attacks and slip hazards. Our product range includes a wide variety of chemical resistant coatings, anti-slip coatings, floor coatings, and resin repair systems.Our chemical resistant coatings are widely used in various industries such as petrochemicals, pharmaceuticals, food and beverage processing, and wastewater treatment plants. These coatings are designed to provide high resistance against chemicals, acids, solvents, and other harsh substances that could damage the surfaces. They are formulated with advanced chemical compounds that can withstand even the toughest conditions and provide long-lasting protection.In addition to chemical resistant coatings, we also offer anti-slip coatings that are designed to provide maximum slip resistance on floors, stairs, ramps, and other surfaces. These coatings are perfect for environments where slip and fall accidents are common, such as factories, warehouses, and public areas. We offer a wide range of anti-slip coatings that are suitable for different types of surfaces, including concrete, metal, wood, and tiles.Our resin repair systems are designed to repair and restore damaged concrete, metal, and other surfaces. We offer a range of resin repair products that are specially formulated to provide high strength, durability, and chemical resistance. These products can be used to repair cracks, holes, and other defects in floors, walls, and other structures.We understand that customer satisfaction is paramount, and that is why we always strive to provide the best quality products and services to our customers. Our team of experienced professionals is always ready to assist you with your requirements and provide you with the best possible solutions. We also offer a range of training programs and technical support to help you get the best results from our products.So if you are looking for high-quality chemical resistant systems, anti-slip coatings, and resin repair products, look no further than (brand name removed). We are committed to providing you with the best products and services that meet your unique needs and exceed your expectations. Contact us today to learn more about our products and services. Keywords: Anti-Static Coating, Resin Repairs, Chemical resistant systems, Anti-Slip Coatings, Floor coatings.